Views: 0 Author: Site Editor Publish Time: 2025-02-20 Origin: Site

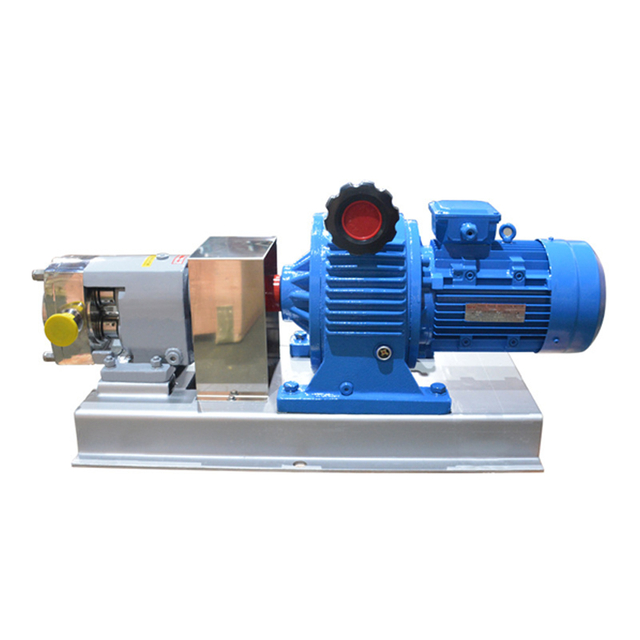

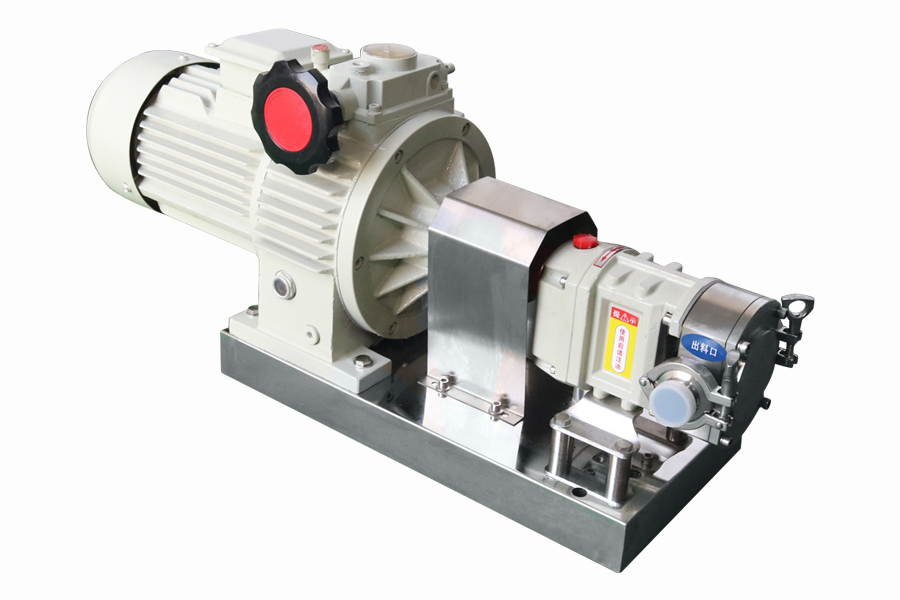

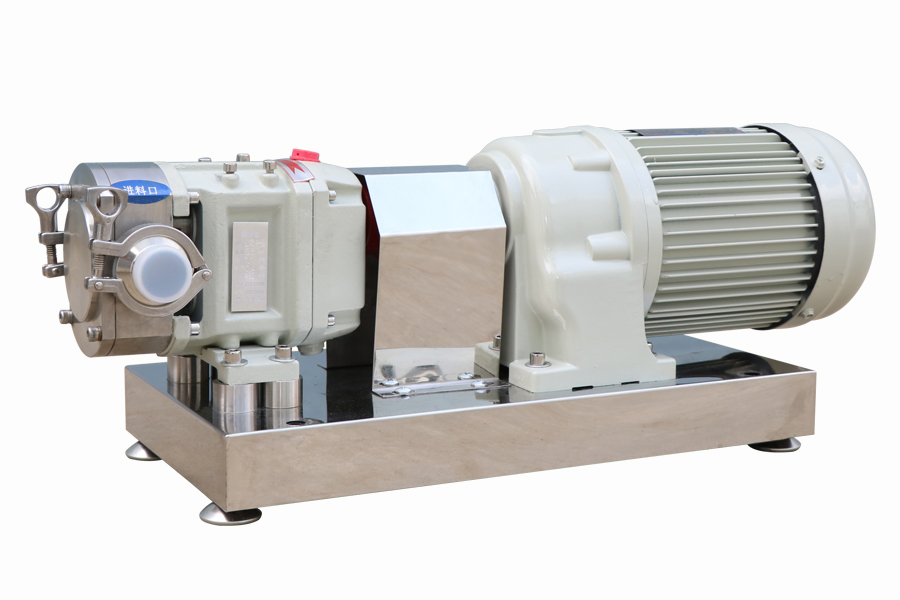

A rotor pump is a type of positive displacement pump that efficiently transfers fluids by trapping and moving them through synchronized rotating lobes. Unlike centrifugal pumps, which rely on velocity to transport fluids, rotor pumps provide consistent flow rates, making them ideal for handling high-viscosity, shear-sensitive, and solid-laden fluids.

JUSH Pump, a trusted leader in rotor pump technology, designs innovative and durable solutions tailored for industries such as food processing, pharmaceuticals, and chemicals. This article explores the different types of fluids best suited for a rotor pump, highlighting its advantages over other pump types.

A rotor pump consists of two counter-rotating lobes that move fluid through a pump chamber. As the lobes rotate, they create a vacuum that pulls fluid into the chamber and then expels it at a controlled rate. This mechanism allows for:

Consistent flow rates regardless of fluid viscosity

Minimal shear force, protecting delicate substances

Low pulsation, ensuring smooth and even fluid movement

Gentle handling of solids, reducing product damage

Due to these benefits, rotor pumps are widely used in industries that require hygienic, efficient, and precise fluid handling.

One of the greatest strengths of a rotor pump is its ability to handle high-viscosity fluids that other pump types struggle with. These include:

Honey and syrups – Thick and sticky fluids that require gentle handling

Oils and lubricants – Both food-grade and industrial oils

Adhesives and resins – Used in construction, packaging, and manufacturing

Molasses and caramel – Common in food production and confectionery

Since centrifugal pumps lose efficiency when handling high-viscosity materials, a rotor pump provides a superior solution by maintaining steady and efficient fluid transfer.

Certain liquids degrade or lose effectiveness when subjected to high shear forces. A rotor pump provides gentle, low-shear handling, making it ideal for:

Dairy products – Milk, cream, and yogurt that require smooth transfer

Cosmetic creams and lotions – Ensuring the preservation of texture and consistency

Pharmaceutical liquids – Safeguarding the active ingredients in medicines

Food emulsions – Such as mayonnaise and salad dressings, preventing ingredient separation

By maintaining product integrity, rotor pumps help manufacturers enhance product quality and shelf life.

Many industries require pumps that can handle fluids containing suspended solids without clogging or excessive wear. Rotor pumps are perfect for:

Fruit pulps and vegetable purees – Used in juice and sauce production

Meat and fish emulsions – Essential for protein-based food processing

Paints and coatings – Ensuring uniform consistency

Pharmaceutical suspensions – Delivering active ingredients in evenly distributed particles

JUSH Pump designs rotor pumps with wide-clearance rotors, allowing for the safe and efficient transfer of solids-containing fluids.

Certain chemicals and industrial fluids require pumps built with corrosion-resistant materials to ensure long-term durability. Rotor pumps made from stainless steel or special coatings are ideal for:

Acids and alkalis – Used in chemical processing

Detergents and disinfectants – Handling aggressive cleaning solutions

Dyes and inks – Used in textile and printing industries

Fine abrasive slurries – Such as ceramic or mineral-based suspensions

JUSH Pump offers customized rotor pump solutions with high-grade stainless steel components to resist corrosive and abrasive damage.

For industries that require strict hygiene standards, such as food, beverage, and pharmaceuticals, a rotor pump ensures:

CIP (Clean-in-Place) and SIP (Sterilize-in-Place) compatibility

Minimal contamination risk

Smooth internal surfaces for easy cleaning

Common applications include:

Beverages (juices, dairy, alcohol)

Infant formula and medical nutrition

Pharmaceutical syrups and vaccines

Personal care products (shampoos, lotions, liquid soap)

JUSH Pump specializes in hygienic rotor pumps that comply with FDA, EHEDG, and 3A sanitary standards.

To help users determine whether a rotor pump is the best choice for their application, the following table compares it with other pump types:

| Feature | Rotor Pump | Centrifugal Pump | Diaphragm Pump | Gear Pump |

|---|---|---|---|---|

| Best for | High-viscosity & shear-sensitive fluids | Low-viscosity fluids | Abrasive & corrosive fluids | High-viscosity fluids |

| Flow Rate Stability | High | Medium | Low | High |

| Pulsation | Low | High | High | Medium |

| Shear Sensitivity | Low | High | Low | Medium |

| Handling Solids | Yes | No | Yes | No |

| Maintenance | Low | Medium | High | Medium |

JUSH Pump provides expert consultation to help customers select the best rotor pump for their specific needs.

Why are rotor pumps ideal for high-viscosity fluids?

Unlike centrifugal pumps, which rely on speed and lose efficiency with thick fluids, a rotor pump moves a fixed volume of fluid per rotation, ensuring consistent and efficient performance.

Can rotor pumps handle fragile food ingredients?

Yes. Rotor pumps use low-shear, gentle action, making them perfect for sensitive food products like fruit purees, dairy, and emulsified sauces.

How do rotor pumps compare to diaphragm pumps?

While both handle abrasive and corrosive fluids, rotor pumps offer smoother flow, lower maintenance, and higher efficiency than diaphragm pumps.

Are rotor pumps suitable for chemical applications?

Yes, when made from stainless steel or corrosion-resistant coatings, rotor pumps can handle acids, alkalis, and industrial solvents without degradation.

How often do rotor pumps need maintenance?

JUSH Pump's rotor pumps are designed for low maintenance, with durable seals and wear-resistant materials, ensuring long service life and minimal downtime.

A rotor pump is an excellent choice for high-viscosity, shear-sensitive, solid-laden, and corrosive fluids. Compared to centrifugal pumps, diaphragm pumps, and gear pumps, it offers greater efficiency, precision, and durability.

JUSH Pump specializes in advanced rotor pump solutions for industries requiring hygienic, durable, and high-performance fluid handling. Whether in food production, pharmaceuticals, or chemical processing, JUSH Pump provides customized solutions tailored to your needs.

For expert recommendations on choosing the right rotor pump, contact JUSH Pump today!