Views: 59899 Author: JUSH Marketing Department Publish Time: 2025-04-21 Origin: Shanghai JUSH Pump

For users who rely on well water as their household water supply, well water pumps and pressure systems are the core equipment for maintaining stable water supply. Whether it's rural homes, farms, or houses in remote areas, choosing the right water pump and pressure system can ensure continuous and stable water flow, meeting the needs of daily life. This article will delve into the working principle, types, pressure system functions, and how to optimize the system to improve efficiency of household well water pumps.

Catalogue

1. Working principle of household well water pump

2. Types and applicable scenarios of household well water pumps

3. Composition and working mechanism of household pressure system

4. Installation and selection guide for water pump system

5. Common problems and troubleshooting of water pumps

6. Maintenance and upkeep strategies for water pump systems

7. Optimization and energy-saving improvement of water pump system

8. Installation and professional advice for water pump system

9. Future Development Trends and Technological Innovation

1. Working principle of household well water pump

Well water pump is the core equipment that extracts groundwater to the ground and transports it to the household pipeline system. The working process can be divided into several main steps:

1.1 Pumping principle

The well water pump generates negative pressure through one or more mechanical devices, forcing groundwater to flow out of the well. For submersible pumps installed inside the well, their working principle is to directly use a motor to drive the impeller to rotate, pushing water out of the well; The jet pump installed on the ground utilizes pneumatic principles to create negative pressure and attract water into the pump body, which is then pressurized and transported to a predetermined location.

1.2 Pressure water delivery

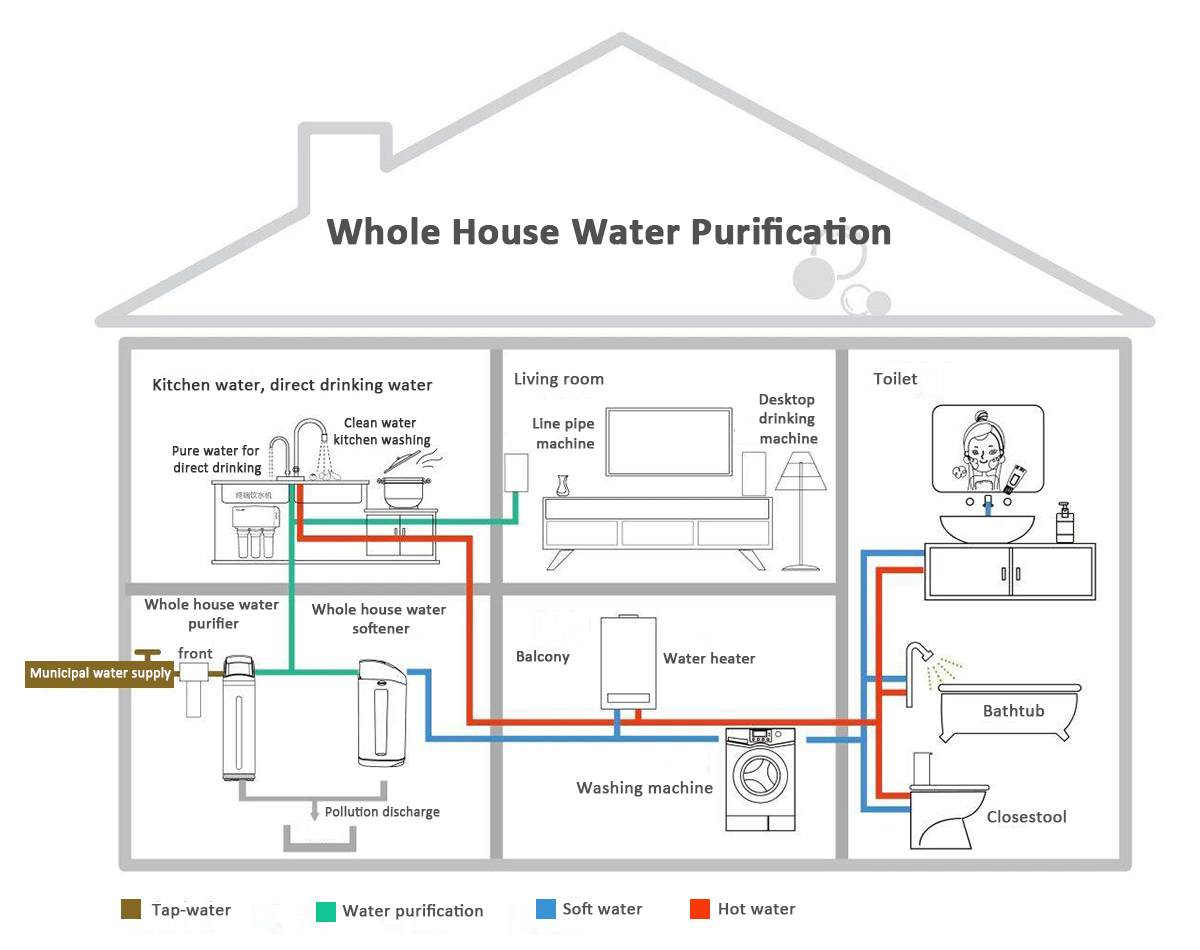

After pumping, the impeller or piston inside the water pump will pressurize the water. The pressurized water is transported to the pressure tank through pipelines to further regulate the water pressure, so that the water flow reaches a stable state and is redistributed to various water points (such as kitchens, bathrooms, gardens, etc.). This process ensures the continuity and balance of household water supply.

1.3 Function of key components

Inlet pipe and filter: prevent sediment and impurities from entering the pump body, ensuring long-term stable operation of the equipment.

Motor and impeller: The motor provides energy to drive the impeller, which is the key to generating water flow and pressure.

Sealing device: prevents water leakage and ensures efficient operation of the equipment.

The above principles and components together constitute the core working mechanism of well water pumps, and are also the foundation for ensuring the safety and efficiency of household water supply.

2. Types and applicable scenarios of household well water pumps

According to the depth of the well, water demand, and installation environment, well water pumps can be classified into various types. Below are several main types of well water pumps and their applicable scope:

Jet pumps are generally installed on the ground, and the well water is sucked into the pump body through a suction pipe for pressurization.

Applicable scenario: Household well water systems with shallow well depths (usually less than 25 feet/about 7.6 meters).

Working principle: Utilize the kinetic energy and suction generated by water jet to make water rise along the suction pipe.

Advantages: Easy installation, convenient maintenance, suitable for daily household water needs.

Disadvantages: When the well depth exceeds a certain range, the efficiency will significantly decrease, and there is a high requirement for the sealing of the suction tube.

The submersible pump is installed inside the well and fully immersed in water. Its working principle is to directly "push" the water out of the well.

Applicable scenarios: Suitable for medium to deep wells or deep wells (with depths exceeding 25 feet, some models can adapt to depths up to 400 feet or more).

Working principle: The motor works in water, directly pushing water from the bottom of the well to the surface with high efficiency.

Advantages: low operating noise, low energy consumption, stable pressurization effect; Adapt to deep well water supply.

Disadvantages: Professional skills are required during installation, and maintenance costs are high. Once a malfunction occurs, it may need to be replaced as a whole.

2.3 Deep Well Jet Pump

Deep well jet pump is between jet pump and submersible pump, which can adapt to deeper wells and can be installed on the ground. It mainly extracts water through pipeline system.

Applicable scenario: Suitable for well water systems with depths between 25 and 100 feet.

Advantages: The design is flexible, easy to maintain, and can balance efficiency and installation costs.

Disadvantages: The performance may not be as good as submersible pumps, and there are higher requirements for the sealing and design of wellhead pipelines.

2.4 Manual pump

Manual pumps are mainly used for emergency water supply or short-term water supply in environments without electricity.

Applicable scenarios: wilderness camping, sudden power outages, or environments with low water demand.

Advantages: Simple structure, easy to use, no need for power supply.

Disadvantages: High physical exertion, low pumping efficiency, not suitable for long-term household water supply systems.

Through the introduction of different types of well water pumps above, consumers can choose the most suitable product based on actual well depth, water demand, and budget, ensuring the long-term stable operation of the well water system.

3. Composition and working mechanism of household pressure system

The pressure system plays a key role in regulating water pressure and stabilizing water flow in household well water pumps. Common pressure systems mainly consist of pressure tanks, pressure switches, check valves, and pressure regulating valves. The following will analyze the functions and working principles of these key components one by one:

3.1 Pressure Tank

Pressure tank is the most important water storage and pressure regulating equipment in well water systems.

Main function: Store a certain amount of pressurized water when the water pump stops working, and maintain the water pressure within the set range through compressed air or diaphragm, thereby reducing frequent pump starts and extending equipment life.

Type:

Bladder type pressure tank: Equipped with a rubber bladder, it can effectively isolate water and air, preventing air from entering the system.

Diaphragm pressure tank: using metal or composite material diaphragm, with high durability and stability.

Traditional air pressure tanks: water and air are directly mixed, making maintenance more complex, and are now commonly used in old systems.

3.2 Pressure Switch

The pressure switch is responsible for monitoring the system water pressure and controlling the start and stop of the water pump according to the set value.

Working principle: When the system water pressure drops to the preset lower limit (such as 30 PSI), the pressure switch will automatically start the water pump; When the water pressure reaches its upper limit (such as 50 or 60 PSI), the water pump will stop running.

Importance: Accurate pressure switches not only ensure that the water pump operates at its optimal state, but also prevent damage to pipelines and equipment caused by excessive water pressure fluctuations.

3.3 Check Valve and Pressure Regulator

Check valve: installed at the outlet of the water pump to prevent pressurized water from flowing back into the pump body, thereby protecting the pump body from backflow damage.

Pressure regulating valve: regulates the water pressure entering the household water supply pipeline, ensuring that the water pressure at each outlet point is balanced and preventing damage to equipment and pipelines due to high water pressure.

3.4 Overall workflow of the system

Start up phase: When household water usage causes a decrease in system water pressure, the pressure switch triggers the water pump to start and extract water from the well.

Pressurized storage: The extracted water enters the pressure tank and maintains a constant pressure through the action of internal air or diaphragm.

Water supply stage: Stable pressurized water is distributed to various water consuming equipment through pipelines, while check valves and regulating valves ensure safety and stability during the water supply process.

Stop phase: When the pressure reaches the set upper limit, the pressure switch automatically shuts off the water pump, and the system enters standby mode until the next water demand.

The efficient collaboration of this entire system not only ensures the continuity and stability of household water supply, but also significantly extends the service life of pumps and related equipment during long-term operation, while improving energy efficiency and safety.

4. Home Water Pump System Installation and Selection Guide

When selecting and installing household well water pumps and pressure systems, consumers need to consider multiple factors. The following is a detailed selection and installation guide:

4.1 Investigation of Well Depth and Water Level

Well depth: Different types of water pumps are suitable for wells of different depths. For shallow wells (less than 25 feet), jet pumps can usually meet the demand; For deep wells, it is recommended to use submersible pumps or deep well jet pumps.

Static water level: Understanding the height of the static water level in the well is an important basis for selection, which can ensure that the suction capacity of the selected water pump meets the actual situation.

4.2 Water demand and flow calculation

Number of family members: Calculate the required flow based on the household population and daily water usage. Generally speaking, it is recommended for a family of 4-6 to choose a high flow water pump to meet the need for using multiple faucets simultaneously.

Water equipment: When multiple points such as kitchens, bathrooms, washing machines, and garden irrigation are used simultaneously, high requirements are placed on the continuous water supply capacity of the water pump and the stability of the pressure system.

4.3 System Configuration and Accessory Selection

Pump power: Choose a pump of appropriate power to avoid difficulty in pumping water due to insufficient power or energy waste caused by excessive power.

Pressure tank capacity: It is generally recommended to choose a pressure tank of 20 to 100 gallons (75 to 380 liters), with the specific capacity determined based on the actual water consumption of the household.

Additional filter: If there are many impurities in the well water, installing a pre filtration device can effectively extend the service life of the water pump and various components of the system.

Electrical protection device: equipped with overload protection, short circuit protection and other safety measures to ensure the stability and safety of the system during long-term operation.

4.4 Installation Environment and Maintenance Conditions

Installation location: The installation environment of the water pump and pressure system should be kept dry, ventilated, and avoid direct sunlight and extreme temperature environments as much as possible.

Convenience of Maintenance: When choosing, it is recommended to consider products with well-known brands and comprehensive after-sales service to ensure timely professional maintenance in case of equipment failure.

5. Common problems and troubleshooting

Despite the increasingly sophisticated design of modern well water systems, some common problems may still be encountered in daily use. The following are common fault phenomena and corresponding troubleshooting and solutions:

5.1 The water pump does not start

Possible reasons: power interruption, pressure switch malfunction, or motor damage.

Solution: First, check the power circuit and fuse, then test whether the pressure switch responds normally. If necessary, please contact a professional to inspect or replace the motor.

5.2 Unstable system water pressure

Possible reasons: insufficient pressure in the pressure tank, aging of the internal diaphragm, malfunction of the pressure regulating valve, or pipeline leakage.

Solution: Regularly check the air pressure inside the pressure tank and replace the bladder or diaphragm if necessary; At the same time, check whether there are leaks in the pipelines and interfaces to ensure that the regulating valve is working properly.

5.3 Frequent startup of water pump

Possible reasons: Insufficient capacity of pressure tank or unreasonable setting of pressure switch.

Solution: Replace the large capacity pressure tank appropriately or adjust the start stop setting of the pressure switch to reduce the number of starts and stops of the water pump, thereby reducing equipment wear.

5.4 Blockage of inlet pipe or water quality issues

Possible reasons: Well water contains a high amount of sediment, impurities, or algae.

Solution: Regularly clean the inlet pipes and filters, and install more efficient pre filtration devices if necessary to ensure clean water quality drawn in by the water pump and extend the system's lifespan.

6. System maintenance and upkeep strategy

Regular maintenance and upkeep are crucial to ensure the long-term efficient operation of household well water pumps and pressure systems. The following is a detailed maintenance strategy:

6.1 Regular Inspection and Testing

Pressure testing: Conduct a system pressure test at least once a year to check if the pressure inside the pressure tank is within the set range and ensure that the pressure switch responds accurately.

Pipeline inspection: Regularly inspect the inlet and outlet pipelines, joints, and sealing devices to prevent water leakage or aging due to long-term use.

Electrical equipment testing: Testing motors, switches, and related electrical control systems to ensure that all electrical components are working properly and prevent short circuits or overload issues.

6.2 Cleaning and Disinfection

Filter cleaning: Regularly clean the filter according to the usage environment to prevent impurities from blocking and affecting the pumping efficiency.

Internal maintenance of water pump: Regularly ask professional technicians to clean the inside of the water pump, remove possible sediment and rust, and keep the equipment in good working condition.

Disinfection measures: If the well water has not been treated for a long time, it is recommended to regularly disinfect the system to avoid bacterial growth and affect water quality.

6.3 Energy saving and Protection Measures

Intelligent control system: Some high-end well water pumps are equipped with intelligent control systems that can automatically adjust operating parameters based on actual water usage, achieving energy conservation and consumption reduction.

Anti freezing and insulation: In cold regions, anti freezing measures should be taken (such as installing insulation layers or indoor equipment) to prevent damage to equipment and pipelines caused by low temperatures.

Emergency plan: Establish an emergency maintenance plan to ensure that measures can be taken quickly in case of equipment failure, reducing the impact on household water use.

7. System optimization and energy-saving improvement

With the continuous advancement of technology, more and more well water systems are paying attention to energy conservation and intelligent management. The following are several optimization measures to improve system efficiency and reduce energy consumption:

7.1 Adopting variable frequency speed regulation technology

Variable frequency water pumps can automatically adjust their speed according to real-time water demand, thereby accurately controlling water flow and pressure.

Advantages: Reduce energy consumption, extend equipment lifespan, and minimize motor losses caused by frequent starting.

Application: Especially suitable for households or commercial places with large fluctuations in water consumption, achieving precise water supply through intelligent speed regulation.

7.2 Optimizing the Capacity Configuration of Pressure Tanks

Reasonable configuration of pressure tank capacity can not only reduce the frequency of water pump start stop, but also provide buffering during water pressure fluctuations.

Suggestion: Choose a suitable capacity pressure tank based on household water usage and actual needs, with a common configuration range of 20 to 100 gallons.

Effect: It not only ensures the stability of water supply, but also significantly extends the service life of water pumps and other components of the system.

7.3 Intelligent Monitoring and Remote Management

By utilizing modern IoT technology, real-time monitoring and data collection of well water systems can be achieved.

Function: Remote monitoring of water pressure, water flow, energy consumption, and fault alarms to promptly identify potential issues.

Benefit: By continuously optimizing system operating parameters through data analysis, automatic maintenance and fault warning can be achieved, greatly improving system reliability and user experience.

7.4 Improving water quality protection measures

The water quality directly affects the efficiency of the water pump and the entire system.

Measures: Install high-efficiency filters, sedimenters, and other devices at the inlet end, regularly check the water quality, and ensure that the system is in good working condition for a long time.

Benefits: Not only does it extend the lifespan of the equipment, but it also provides a safer and cleaner water environment, meeting the high demands of modern consumers for health and environmental protection.

8. System installation and professional advice

The installation of household well water pumps and pressure systems requires professional technical support. To ensure optimal system installation, the following are professional recommendations before and after installation:

8.1 Preliminary Planning and Design

On site investigation: Please have professional technicians go to the site to conduct detailed inspections of the well depth, static water level, and surrounding environment, providing data support for system design.

System design: Develop a detailed system plan based on detection data, including pump model selection, pipeline layout, pressure system configuration, and electrical circuit design.

Cost budget: Clearly define the cost of equipment procurement, installation, and post maintenance, and choose a cost-effective solution.

8.2 Installation and Debugging

Professional installation team: Select a qualified professional installation team to ensure that all parts of the system are installed in place and comply with national standards and safety regulations.

On site debugging: After installation, conduct comprehensive debugging to ensure that the water pump starts, stops, pressurizes, and supplies water normally.

System testing: Through long-term operation testing, observe whether the system has problems such as water pressure fluctuations, water leakage, or electrical faults, and make timely adjustments.

8.3 User Training and After sales Service

Usage training: Provide users with detailed usage instructions and maintenance manuals to help them master basic operation and daily maintenance knowledge.

After sales support: Establish a comprehensive after-sales service system, provide regular testing, technical support, and emergency maintenance services to ensure the long-term stable operation of the system.

9. Future Development Trends and Technological Innovation

With the continuous improvement of environmental protection and energy conservation awareness, household well water pumps and pressure systems will present the following major development trends in the future:

9.1 Intelligence and Remote Monitoring

Through the Internet of Things, big data, and cloud platforms, comprehensive intelligent monitoring and management of well water systems can be achieved, including real-time data collection, fault warning, and remote control, providing users with a more convenient operating experience.

9.2 Continuous breakthroughs in energy-saving technologies

By adopting advanced technologies such as variable frequency speed regulation, energy recovery, and solar power supply, the well water system can significantly reduce energy consumption while ensuring water supply stability, in line with the modern concept of green environmental protection.

9.3 Material and Process Improvement

The application of new corrosion-resistant materials and advanced processes will further improve the durability and safety of water pumps and pressure systems, extend equipment life, and reduce maintenance costs.

9.4 Personalized Customization

With the diversification of consumer demands, the design and configuration of well water systems will become more personalized. Manufacturers can provide customized system solutions based on the specific needs of different users, thereby enhancing market competitiveness.

As the core components of groundwater resource development and utilization, the scientific and rational design and efficient and stable operation of household well water pumps and pressure systems are crucial. Through a comprehensive analysis of the working principle of water pumps, the advantages and disadvantages of different pump types, the synergistic effects of various components of the pressure system, and installation and maintenance techniques, consumers can choose the most suitable equipment and configuration plan based on the actual situation of their own well water.